Choosing the Right Conductor for Subsea Cables: Copper or Aluminum?

- August 14, 2025

- Posted by: Sarah Chuan

- Category: Submarine Cable Networks

Choosing The Right Conductor for Subsea Cables: Copper or Aluminum?

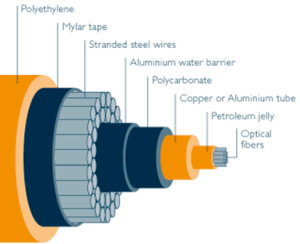

Submarine Optical Cables have been deployed since 1988, starting with TAT-8. Optical signal goes through attenuation when it travels down the fiber, and after a few hundreds of kilometers, it needs to be amplified to reach its destination, which is typically thousands of kilometers away. In this journey, dozens of amplifiers may be required. These amplifiers are usually EDFA (Erbium-Doped Fiber Amplifier), though Raman amplification is also a possibility.

EDFA is a fully optical amplifier (O/O/O), meaning that it receives an optical signal, amplifies it in optical domain, and outputs an optical signal. It uses a pump laser (typically 980nm or 1480nm) to excite erbium ions, transferring energy to the incoming signal at ~1550nm. This pump laser requires electric current to operate and generate an optical signal.

In terrestrial systems, provision of electricity is not an issue as multiple sources of power are available from commercial mains, batteries, or generators. However, powering optical gear in the subsea environment is quite a challenge. Hence, the electric current travels along with the optical signal in the same submarine cable. This electric current is generated by the Power Feeding Equipment (PFE) which is typically installed in Cable Landing Station (CLS). Since all the amplifiers are in series, they are powered in series with the same current, making it a “constant-current system”. However, the voltage is highly variable, depending on the length of the submarine cable, number of repeaters, and number of fiber pairs (each fiber requires a separate repeater). In addition, the resistance of the copper conductor plays an important role in determining the power feed budget.

Copper has been traditionally used as the conductor due to its lower resistance and easier availability. However, recently, 2Africa and Meta’s Waterworth have used Aluminum conductor to carry electric current. Now let’s compare the two materials used as conductors with respect to the following parameters:

- Resistivity

- Density

- Price

- Availability

Now, to calculate the resistance, we use the following formula:

R = ρ * (L / A), where:

- R is the resistance in ohms (Ω).

- ρ (rho) is the resistivity of copper (approximately 1.68 x 10-8 Ω·m).

- L is the length of the pipe/conductor in meters (m).

- A is the cross-sectional area of the pipe/conductor in square meters (m2).

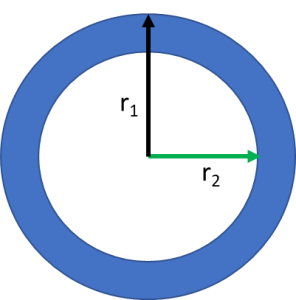

The cross-sectional area of the conductor is given as:

A = π r12 – π r22 = π (r12 – r22)

If the outer diameter of the conductor is 4mm and inner diameter is 3mm, then the cross-sectional area comes out to be:

A = π (42 – 32) = 22 mm2 =22 x 10-6 m2

For a typical submarine cable of 1km (1000m), with copper conductor’s cross-sectional area of 22 mm2 (0.000022m2) the resistance comes out to be:

R = 1.68 x 10-8 x 1000 /0.000022 = 0.76 Ω

Now, if we replace our copper conductor with aluminum conductor of exact same diameter and thickness, then its resistance will be:

R = 2.82 x 10-8 x 1000 /0.000022 = 1.28 Ω

However, the ratio of the densities of Copper vs Aluminum is: 8.96/2.71 = 3.3.

It means that we can add more Aluminum to have a larger cross-sectional area and hence have a comparable resistance. With a price differential of 3.92, this additional weight will still be cheaper than the heavier copper, hence resulting in comparable resistance.

Now, let’s calculate the volume and mass of the conductor:

- Density = m/V, m is mass and V is volume

- Volume of the conductor: V = A x L, where A is the cross-sectional area and L is the length of the conductor (1km (1000m) in this example).

- The mass of the conductor: m = Density x Volume = Density x A x L

For copper conductor:

- Density = 8960 x kg/m3

- m = 8960 x 22 x 10-6 x 1000 = 197 kg

- Price: (@$9800/Metric Ton) = $1931

For Aluminum conductor (having same cross-sectional area):

- Density = 2710 x kg/m3

- m = 2710 x 22 x 10-6 x 1000 = 60 kg

- Price (@$2500/Metric Ton) = $150

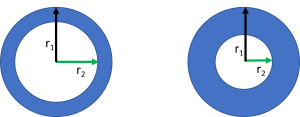

For Aluminum conductor with additional material:

To bring down the Aluminum resistance to that of Copper, we need to put more material, i.e., enhance the area. Since the resistivity ratio of Aluminum to Copper to is 1.68, we need to enhance its cross-sectional area accordingly:

- A = 1.68 x 22 = 37 mm2

- R = ρ * (L / A) = 2.82 x 10-8 x 1000 /0.000037 = 0.76 Ω (Same as that of Copper)

- m = Density x A x L = 2710 x 37 x 10-6 x 1000 = 100 kg

- Price ($2500/Metric Ton): $250

Summary

In summary, copper has been used traditionally for all electric current requirements but aluminum is emerging as a lighter, more cost-effective alternative. As per above comparison, Copper conductor of 1km length and 22mm2 cross-sectional area weighs 197kg and costs about $1931. An aluminum conductor of equivalent resistance will require a cross-sectional area of 37 mm2 but weighs only 100 kg (about 51% of copper) and costs just $250 (about 13% of the price). These cost savings can be transferred to the buyer and seller, while the lower weight simplifies installation and makes fault recovery easier. These advantages that cannot be taken lightly.

Contact us today to find out how we can help you succeed.

Follow us on LinkedIn to stay tuned to our weekly updates of the latest developments in the Telecom/IT industry and popular courses that we offer.

Upcoming courses:

Submarine Cable Systems with IPLC and IP Transit Services (October 22-24, 2025)

Telefocal Certified Submarine Cable System Expert (TC-SCSE) (February 2-6, 2026)